Pllaka izoluese prej silikat të kalciumit.

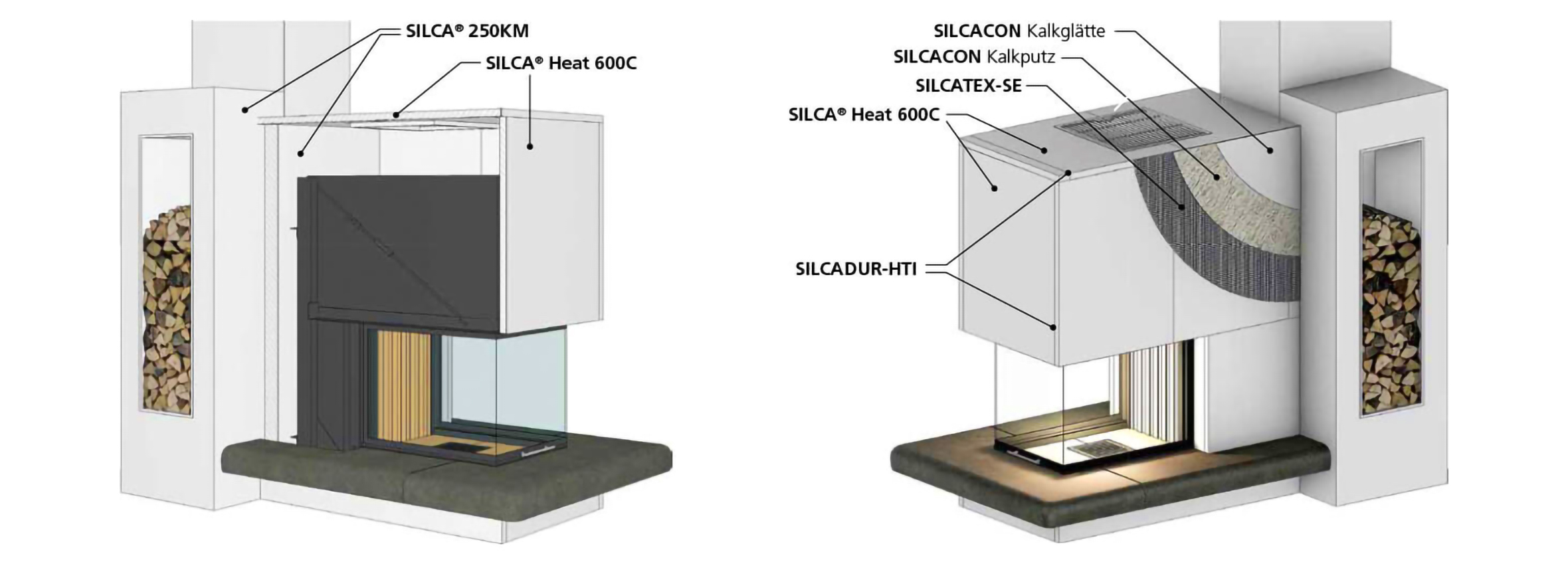

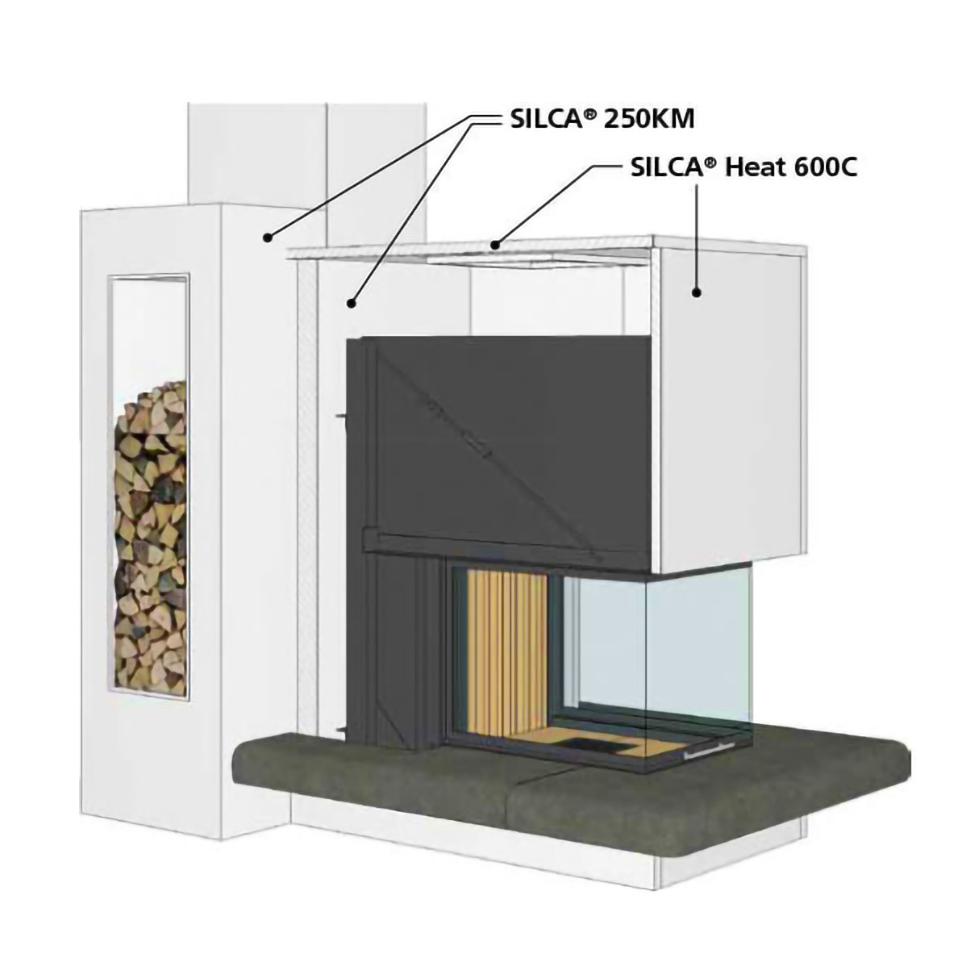

Për shumë vite pllaka jonë e silikatit të kalciumit SILCA®250KM ka qenë një material izolues për sobat me pllaka dhe vatrat e zjarrit i autorizuar nga Deutsches Institut für Bautechnik DIBt (Instituti Gjerman për Inxhinierinë e Ndërtimit). Pllaka përdoret pothuajse në të gjitha vendet evropiane dhe konsiderohet si produkt premium Made in Germany në zonën e tij të veçantë. Gjithashtu, me SILCACON ne zhvilluam një sistem të plotë për ndërtimin e këtyre kaminave.

SILCA 250KM

Panele izolimi prej silicit dhe kalciumit.

SILCA® 250KM zëvendëson muret mbrojtëse të zjarrit dhe izolimin termik (pllaka gipsi & lesh guri) në vetëm një material ndërtimi dhe jo vetëm për këtë arsye garanton rezultate më të favorshme sesa produktet konkurente. Trashësia e kërkuar e shtresës izoluese përcaktohet në bazë të udhëzimeve të montimit të prodhuesve të oxhakëve, rregullave teknike TR-OL dhe rregulloreve të mëtejshme kombëtare. Në rastët individual të aplikimit dhe aty ku është e përshtatshme, duhet të sigurohet një ventilim aktiv i ajrit.

Komponentët kryesorë të paneleve SILCA janë gëlqere dhe rërë. Këto janë fiziologjikisht të sigurta dhe të klasifikuara si material ndërtimor në përputhje me mjedisin. Kjo është e garantuar nga objektet tona moderne të prodhimit, kontrolli i përhershëm i cilësisë, mbikëqyrja dhe certifikimi i jashtëm sipas DIN EN ISO 9001: 2008. Përputhshmëria mjedisore është e certifikuar nga deklarata e produktit mjedisor sipas ISO 14025 dhe EN 15804 të lëshuar nga Institut Bauen und Umwelt eV (Instituti gjerman për ndërtim dhe mjedis), deklarata nr. EPD-CSP-20180010-IBC1-DE.

Panelet janë të presuar në një nga kampresoret më të mëdhenj në botë për prodhimin e paneleve silikat të kalciumit në një dimension prej 3.000 x 1.250 mm. Dimensionet standarde janë 1.250 x 1.000 mm, 1.250 x 500 mm dhe 1.000 x 625 mm. Trashësia standarde varion nga 30 mm deri në 100 mm. Një veti më tepër e cilësisë së paneleve silikate të kalciumit SILCA është sipërfaqja e ngurtë dhe kundër pluhurit. Prandaj, një fushë tjetër e aplikimit është veshja e oxhakut.

Përveç dimensioneve standarde prerjet individuale mund të prodhohen direkt në fabrikë sipas kërkesës. SILCA® 250KM mund të trajtohet me vegla standarde të përpunimit të drurit dhe gjithashtu mund të montohet vetëm me vidha.

Përparësitë tuaja në një shikim.

- Ruajtjen e hapësirës për shkak të trashësisë së hollë izoluese.

- Jo-djegshme.

- Material ndërtimor në përputhje me mjedisin.

- Fizikisht të sigurt.

- Mur mbrojtës nga zjarri dhe izolim termik në një material të vetëm ndërtimi.

- Panele me dimensione të mëdha.

- Trajtim dhe montim i lehtë.

- Hedhje të lehtë si mbetje ndërtimi.

- I aplikueshëm për izolim dhe ndërtim.

Detaje teknike

| Approved for Germany | General Construction Technique Permit |

| Approved for Switzerland | No. Z-43.14-117 |

| RISE FR Certification | Fire Safety Certificate No. 15202 |

| CE Certificate | 120-0238 (50mm) |

| Fire performance | 0432 CPR-00697-01 |

| Bulk density (± 10%) | Euro class A1 |

| Porosity | 250 kg/m³ |

| Compressive strength | Approx. 90 % |

| Heat transmission resistance at | > 1.4 MPa |

| 40 mm board thickness | ≥ 0.5 m² K/W |

| Thermal conductivity λ at 200 °C | < 0.1 W/m K |

| Thermal expansion at 500 °C | 0.2 % |

| Standard size in mm | 3,000x1,250, 2,000x1,250, 1,500x1,250, 1,500x1,250, 1,250x500, 1,000x625, 625x500 |

| Standard thickness in mm | 30-100 |

SILCAHEAT 600C

Panele termoradiatore për oxhakë.

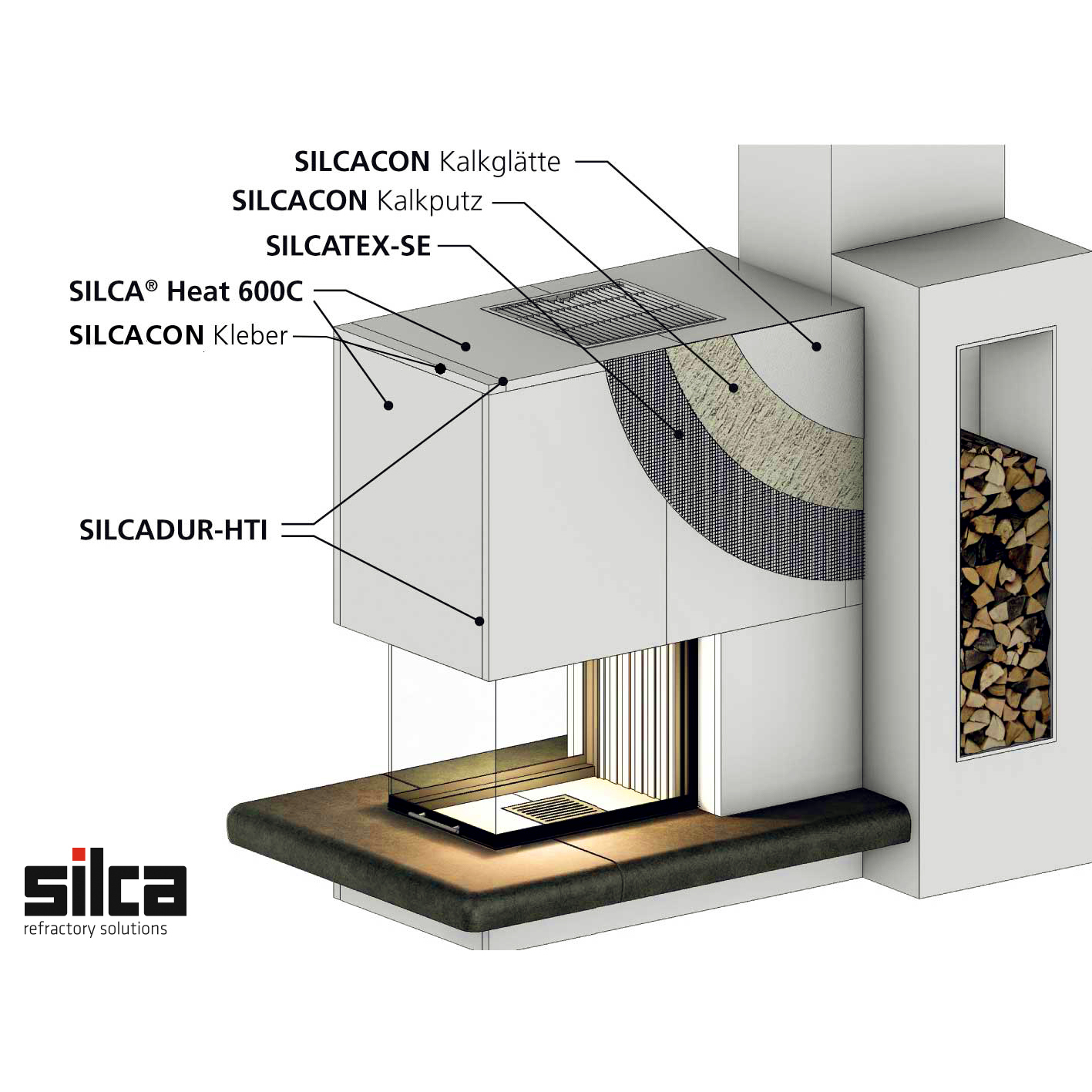

SILCAHEAT® 600C është një penel i ri për veshjen e oxhakut. Ai kombinon rrezatimin natyror termik në funksionimin e oxhakut me kërkesat moderne për një material ndërtimi për montimin e lehtë dhe të shpejtë të oxhakut.

SILCAHEAT® 600C është një material hibrid i qëndrueshëm ndaj temperaturës së lartë, i përbërë nga silikat kalciumi dhe karboni. Për shkak të proporcionit të lartë të grafitit, paneli i ndërtimit ka karakteristika të shkëlqyera ndaj nxehtësisë për veshjen e oxhakut.

SILCAHEAT® 600C nuk është një panel izolues!

SILCAHEAT® 600C është certifikuar nga Materialprüfungsamt NRW (Zyra e Testimit të Materialeve të Nordrhein-Westfalia).

SILCAHEAT® 600C është një panel montues për vatrat e oxhakut të gjeneratës më të re. Duke qenë i aplikueshëm deri në 1000°C, ai bind me peshën e tij të vogël dhe njëkohësisht me forcën të lartë të presionit dhe stabilitetin të shkëlqyer të buzave. Ngrohja rrezatuese jepet në dhomë në një mënyrë të rehatshme dhe homogjene. SILCAHEAT® 600C është rezistent ndaj goditjes termike, pavarësisht përshpërndarjes e mirë termike të saj ka vetëm një zgjerim shumë të ulët termik. Natyrisht paneli i veshjes e oxhakut nuk përmban gëlqere. Prerjet dhe mbetjet mund të asgjësohen si mbeturina ndërtimore.

Trajtimi i SILCAHEAT® 600C është i lehtë, i shpejtë dhe i sigurt. Panelet mund të trajtohen me vegla standarde të përpunimit të drurit dhe të lidhen midis tyre me ngjitësin SILCACON. Panelet mund të montohen vetëm me vidha, kjo shumëfishon mundësitë e montimit. Sipas deshirave të klienteve SILCAHEAT® 600C panelet e veshjes per vatrat e oxhakut mund te suvatohen ose te zbukurohen me gure natyrale ose pllaka pas montimit.

Suva me gëlqere SILCACON dhe lëmues me gëlqere SILCACON mund të përdoren për suvatimin e panelit i veshjes për vatrat e oxhakutSILCAHEAT® 600C. Për shkak të temperaturave të larta nuk duhet të aplikohet shtresa e parë SILCACON. Megjithatë, rekomandohet një para-trajtim i panelit me SILCADUR HTI impregnation.

Suva është e përforcuar me pëlhurë rrjetë qelqi SILCATEX-SE rezistente ndaj nxehtësisë.

Përparësitë tuaja në një shikim.

- Jashtëzakonisht të lehta.

- Stabilitet optimal.

- Saktësi shumë të mirë dimensionale.

- Vetitë e mira të rrezatimit të nzxehtësisë.

- Zgjerim jashtëzakonisht të ulët termik.

- Jo-djegshme.

- Vetë-mbështetës dhe dimensionalisht i qëndrueshëm.

- Montim me ngjitës dhe / ose vidha.

- Kursim i madh i kohës në montim.

- Kombinim optimal i materialit me SILCA® 250KM.

- Kompatibile mjedisore.

Detaje teknike

| Product norm | DIN EN 14306 |

| CE Certificate | 0432-CPR-00697-01 |

| Bulk density | 650 kg/m³ |

| Fire performance | Euro class A1 |

| Application temperature | 1,000°C |

| Compressive strength | 7.0 MPa |

| Flexural strength | 3.0 MPa |

| Thermal expansion at 500 °C | -0.03% |

| Standard size in mm | 1000x625; 1250x500; |

| Standard thickness in mm | 1250x1000 |

| Thickness | 25 and 35 mm |

SILCACON

Plaster system for SILCA® 250KM and SILCAHEAT® 600C

SILCA® 250KM and SILCAHEAT® 600C allows a fast, simple and safe lining of fireplaces with inactive surface. According to the customer’s desire SILCA® 250KM may be plastered or decorated with natural stone or stove tiles.

In this case the large-sized insulation board is used as construction board and applied in the area of blankets, side claddings or wooden panels. Even special individual customer demands like e.g. the installation of flat screens can be easily realized. The separation distances within the heating chambers and the ventilation grids have to be executed according to the manufacturer instructions and technical rules.

The SILCACON system consists of different components which complement one another. Therefore, it meets the most different customers’ desires regarding the surface finish. SILCACON – simple, fast and safe lining of modern fireplaces!